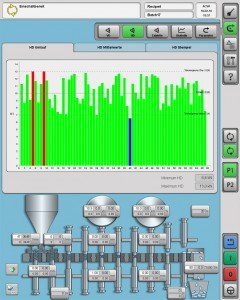

TabControl combines machine and process control in a single system. The hardware is installed in an extra stainless steel control cabinet integrated into the machine’s panelling. As an alternative, we also offer a detached option with the power electronics and control systems located in an external control cabinet. The operating unit can be mounted either within the control cabinet or on a swivel arm.

| ECO | Comfort | Performance | |

|---|---|---|---|

| Displays individual compression pressures for pre and main compaction force | X | ||

| Trend for pre and main compaction force averages | X | ||

| Reduced punches | X | ||

| Compression force monitoring, individual punches | X | ||

| Compression-pressure regulation via the fill depth or cylindrical height main compression | Fill depth | Fill depth | X |

| Motorised adjustment of fill depth, cylindrical height and upper punch penetration including positioning measurement | X | ||

| Sampling | X | ||

| Individually selected tablets using an air-ejection nozzle | X | ||

| Real-weight control with interface to tablet-control system | X | ||

| Identifying bad tablets via main gate | X | X | X |

| Interface to peripheral equipment, e.g. dust extractor or container changer | X | X | X |

| Validation package (standard or as build) | X | X | X |

To date we have reconditioned more than 50 tablet presses from the following manufacturers:

top